Chocolate Week: Exploring the Cocoa Supply Chain

13 octubre 2023

For each day of Chocolate Week 2023, we will be sharing an insight into each stage of the cocoa supply chain, shining a light on the people and the process behind our favourite product.

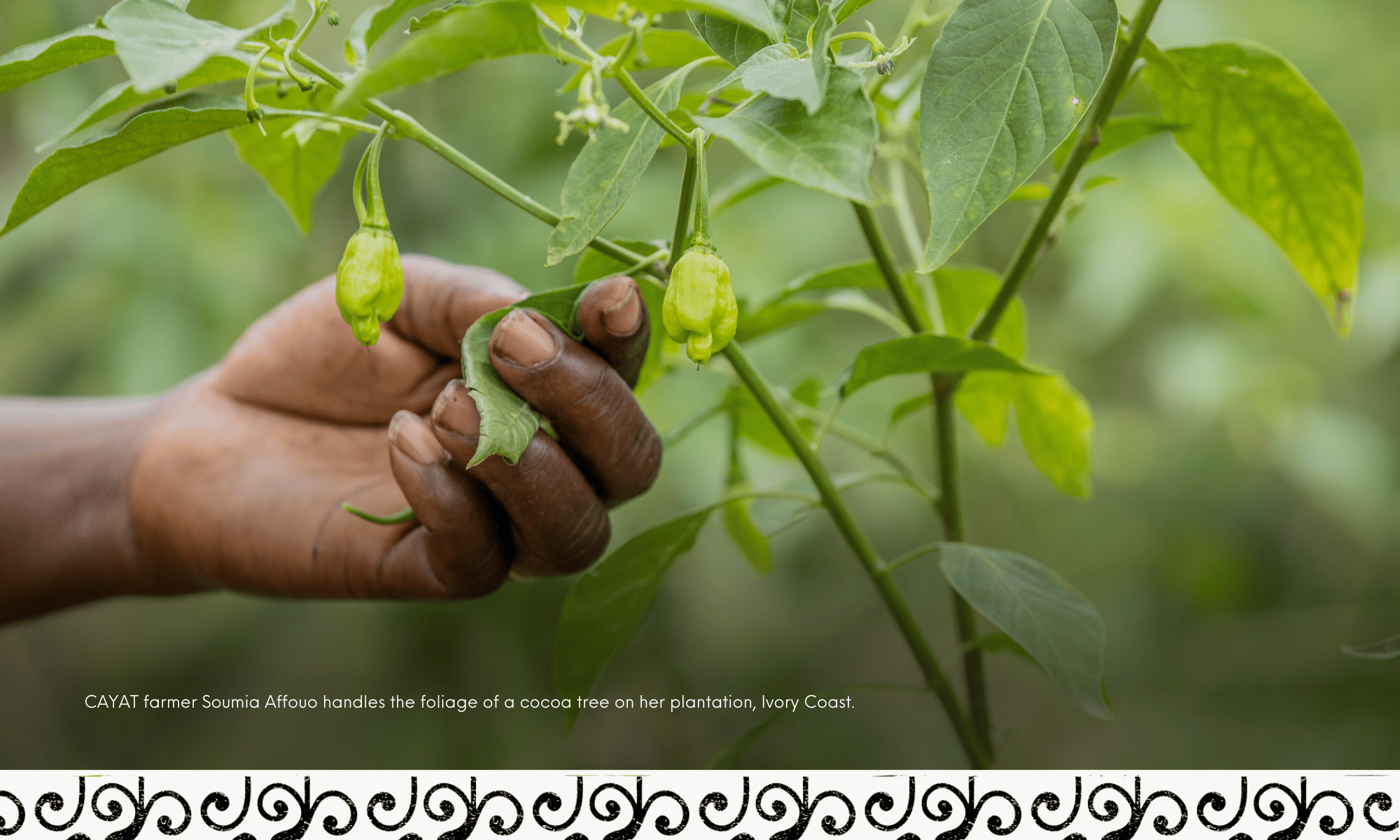

Stage 1: Growing Cocoa Trees

As we explore the cocoa supply chain throughout #chocolateweek, we begin with the growing of cocoa trees. Cocoa trees grow in tropical regions with hot and humid climates including Africa, Central America and South America (particularly in Ivory Coast, Ecuador and Indonesia). These trees produce the raw material used across the cocoa industry: the cocoa pod – which is actually a fruit! And each pod contains somewhere between 20 to 50 cocoa beans – which are actually seeds! 🌴

Still with us? If one thing is clear, though, it is that these cocoa trees require specific conditions to thrive. They often grow under banana, plantain and palm trees as they offer a protective shadow. Whilst cocoa trees tolerate a variation of soil types, they remain vulnerable to insufficient amounts of water: rainfall must be plentiful, with levels of between 1,500mm and 2,000mm desirable throughout the year 🌧️

When maintained well, cocoa trees can live up to 100 years and remain most productive for 25 to 30 years. To keep them sweet, the farmers we work with implement good agricultural practices such as weeding, pruning, applying fertilizer, pest and disease controls 🎛️

Stage 2: Harvesting and Pod Breaking

Cocoa trees produce ripe pods in two cycles of six months within a general crop season. After a three to four week window, the beans begin to germinate and the pods become unripe and unsuitable for harvest 🗓️

Cocoa bean processing begins by harvesting these cocoa pods, which involves removing them from the tree using machetes and making a clean cut through the stalk with the sufficiently sharpened blade 🔪

The best way to open pods is to use a wooden club which, if it strikes the central area of the pod, causes it to split into two halves. It is then easy to remove the beans by hand 👐

At this stage, wet cocoa beans cocoa beans are revealed and then scooped out of their pods and placed in baskets or containers, where they will be transported to a processing facility. If the pods are opened in planting areas, the discarded husks can be distributed throughout the fields to return nutrients to the soil 🌻

Stage 3: Fermenting and Drying

Once the cocoa beans arrive at the processing facility, it is time for them to undergo the fermentation process. This step is quintessential to break down bitter compounds and develop the distinctive flavours and aromas of the chocolate. Overly fermented cocoa beans can produce an acidic taste, whilst poorly fermented beans can develop little cocoa flavour 👎

Fermentation is achieved by piling the beans up and covering them with mats or banana leaves. The beans will then release moisture and produce heat as they are exposed to the sun, leading to the breakdown of the pulp surrounding the beans. This process can last from three to seven days 🗓️

After fermentation, the cocoa beans spend up to two weeks drying in the sun, spread out on mats, trays or concrete floors using a rake to ensure aeration and even drying times. As the beans lose moisture, the cocoa flavour continues to develop. The drying process process is complete when the moisture content of the beans is reduced to about 7% 🌞

This stage is critical: a slow drying process will result in a poor colour, low acidity and a proliferation of mould, whilst a fast drying process will increase the acidity of the flavour 🤒

Stage 4: Sourcing and Marketing

Stage 5: Packing and Shipment

Once graded and stored within cargo vessels, cocoa beans are shipped, either in new jute bags or in bulk. Shipping cocoa beans in bulk is becoming increasingly popular as a result of its affordability compared to conventional shipment in jute bags 🛄

Loose cocoa beans are loaded either into shipping containers or directly into the hold of the ship. This is described as the ‘mega-bulk' method and is often adopted by larger cocoa processors ⛴️

It is fundamental that the cocoa container is protected from adverse weather conditions. Freezing temperatures can result in the beans breaking down and spoiling, whilst exposure to intense heat can carry a risk of further fermentation and perhaps the growth of mould. For this reason, cocoa should always be ‘stowed’ in a cool, dry place offering good ventilation 🌡️

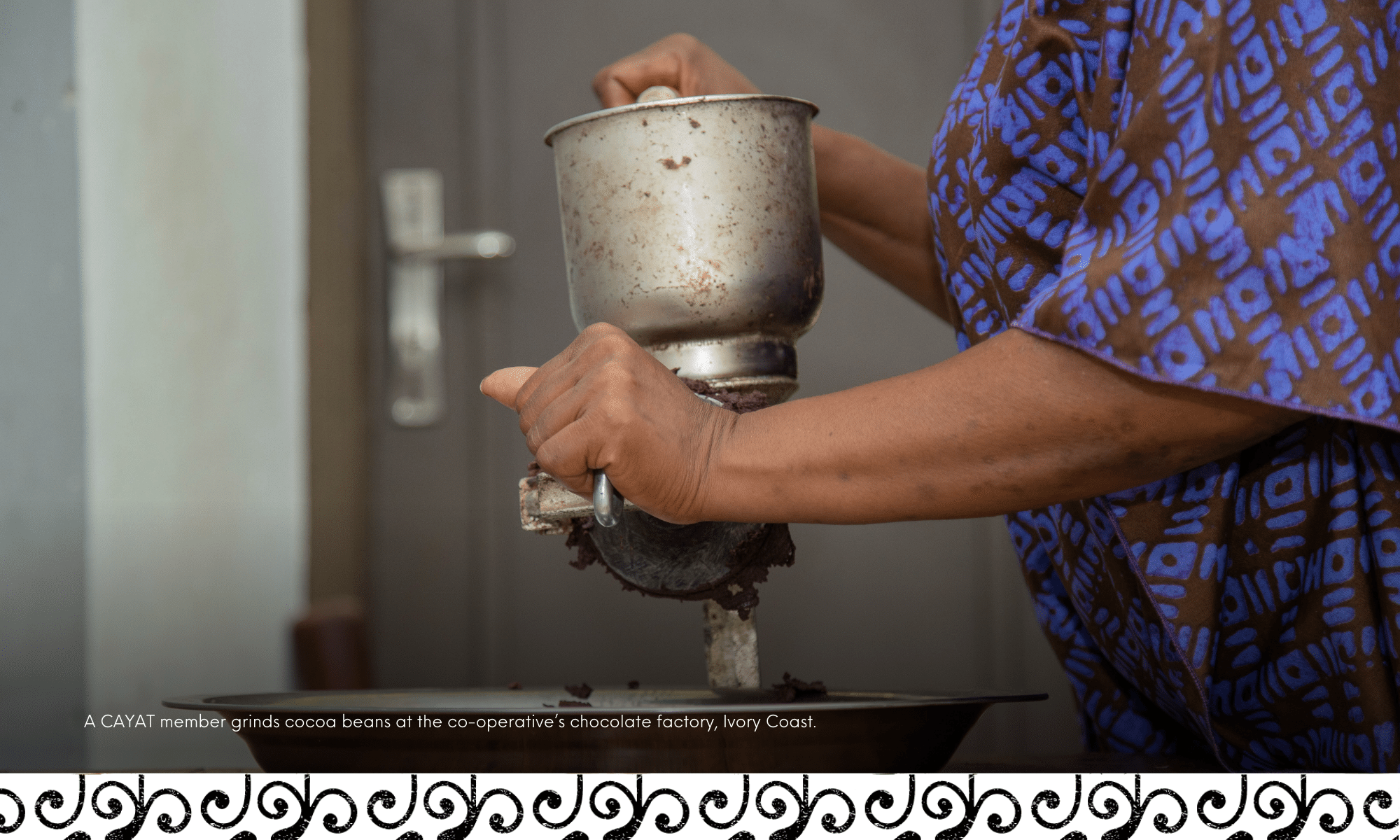

Stage 6: Roasting and Grinding

Once shipped, cocoa beans must be roasted to reduce their water content and extract their rich aromas and flavours. This can be achieved by roasting the beans at temperatures of 110 to 150 degrees centigrade in either small batches (batch roasting) or large quantities using a conveyor system (continuous roasting). The roasting process develops the cocoa’s aromatic compounds, flavour profile complexity and depth of dark colour 🎨

After roasting, the cocoa beans are cooled. At this stage, the outer shell, known also as the husk, is removed from the beans. The beans are then broken down into smaller pieces called cocoa nibs. Once removed, the shells covering the nibs can be sold to fertiliser producers and used as agricultural mulch 🚜

Meanwhile, the cocoa nibs are ground under high temperatures into ‘cocoa liquor’ – a paste which contains both cocoa butter and cocoa solids. The cocoa liquor is then pressed through a fine sieve to leave a solid material called ‘cocoa cake’: the extracted product is cocoa butter. The cocoa is either pulverized into cocoa powder, which is then used in the production of chocolate products, or broken into smaller pieces and sold in generic cocoa markets 💱

The processing stage typically encompasses roasting and grinding of cocoa beans. In the past, these operations were performed almost entirely in importing countries, but, nowadays, origin countries are also increasingly engaged in processing 🗺️

Once shipped, cocoa beans must be roasted to reduce their water content and extract their rich aromas and flavours. This can be achieved by roasting the beans at temperatures of 110 to 150 degrees centigrade in either small batches (batch roasting) or large quantities using a conveyor system (continuous roasting). The roasting process develops the cocoa’s aromatic compounds, flavour profile complexity and depth of dark colour 🎨

After roasting, the cocoa beans are cooled. At this stage, the outer shell, known also as the husk, is removed from the beans. The beans are then broken down into smaller pieces called cocoa nibs. Once removed, the shells covering the nibs can be sold to fertiliser producers and used as agricultural mulch 🚜

Meanwhile, the cocoa nibs are ground under high temperatures into ‘cocoa liquor’ – a paste which contains both cocoa butter and cocoa solids. The cocoa liquor is then pressed through a fine sieve to leave a solid material called ‘cocoa cake’: the extracted product is cocoa butter. The cocoa is either pulverized into cocoa powder, which is then used in the production of chocolate products, or broken into smaller pieces and sold in generic cocoa markets 💱

The processing stage typically encompasses roasting and grinding of cocoa beans. In the past, these operations were performed almost entirely in importing countries, but, nowadays, origin countries are also increasingly engaged in processing 🗺️

Stage 7: Manufacturing and Distribution

To manufacture chocolate, cocoa liquor and butter are mixed with ingredients such as sugar, vanilla, milk and emulsifying agents. They then undergo a process of refinement through a series of rollers 🥛

In recent times, an additional process called ‘conching’ will be performed, which involves the continuous mixing, grinding and kneading of chocolate mass over a period of a few hours up to several days, using a specially designed conche machine. This step attributes to the viscosity, texture and flavour of the finished product 🥄

The resulting mixture, often called “couverture”, is shipped in tanks in liquid or solid form. Alternatively, it can be tempered and poured into moulds, for the use of confectioners and bakers. In some cases, ‘couverture’ chocolate is used in-house to produce consumer products 🍫

After an epic journey, the cocoa bean arrives at the final frontier: your local shop. The final step of the cocoa supply chain involves packaging, commercial marketing and retailing. Some chocolate manufacturers have their own branded retail stores, allowing them to capture a wider base of consumers

Chocolate retailing markets can be categorised in multiple ways, with each category providing specific market opportunities. These involve flavours (dark, milk, white) or sales categories (seasonal, premium or basic)

Interested in taking a trip to a chocolatier near you? Here are some of our top picks:

Newcastle: Hotel Chocolat

North Yorkshire: The Chocolate Factory

Cumbria: Kennedy's Fine Chocolates

Devon: Chococo